PP Woven laminated with PP

High-grade BOPP bag with high mechanical strength, firmness, no deformation when stretched, high impact resistance and loading capacity.

- Type bag: High-grade BOPP bag with high mechanical strength, firmness, no deformation when stretched, high impact resistance and loading capacity.

– Material: PP plastic

– Weight loading: up to 50kg

-

1. BOPP bag features:

In addition to inheriting the durability characteristics of PP woven bags, BOPP bags have many of the following advantages:

– Clear, realistic images and colors.

– Has a deep surface coverage, helps the ink to print beautifully, without losing focus

– High color fastness, hard to fade.

– High aesthetics, increase the professionalism of the product -

2. Application

With the above advantages, BOPP bags are widely used in many fields, especially agriculture, industry, construction and chemicals; can be mentioned as packaging for rice, fertilizer, animal feed, coal, coffee, flour, sugar, seeds, etc.

-

3. Stavian Binh Thuan technology and production chain

Using modern equipment and machines such as looms Starlinger – Austria, Lohia – India, Newlong – Japan can meet a large quantity of packaging and produce high quality finished products.

Using direct Flexo or gravure printing technology, up to 12 colors can be printed on 2 sides or 6 colors on 1 side.

SBT’s products always undergo the most rigorous evaluations for quality, always ensure modern production processes and are recognized through ISO 9001: 2015 certifications, ISO 14001: 2015 certifications, FSSC 22000, Halal certification for the market of Muslim countries.

-

4. Standard specification:

– Size: 40-75 cm in tube form

– Color: The color according to the customer’s request

– Printing: Can print up to 12 colors on 2 sides

– Density: 7-12 needles/inch

– Weight: 56 – 140 gsm

– Coated quantity: 12 – 23 gsm

– BOPP quantity: 18-20 gsm

– Liner bags: HDPE | LDPE | LLDPE

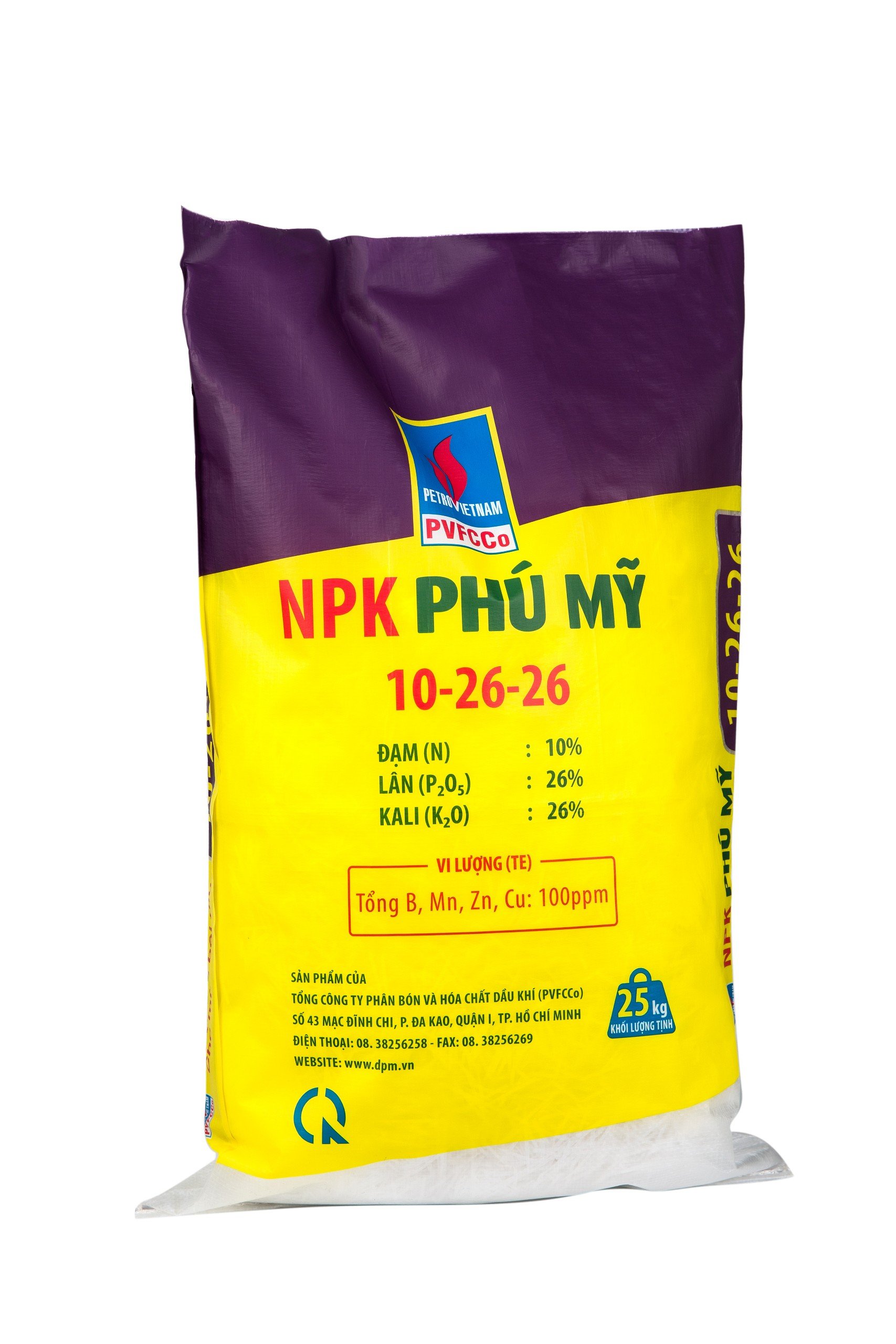

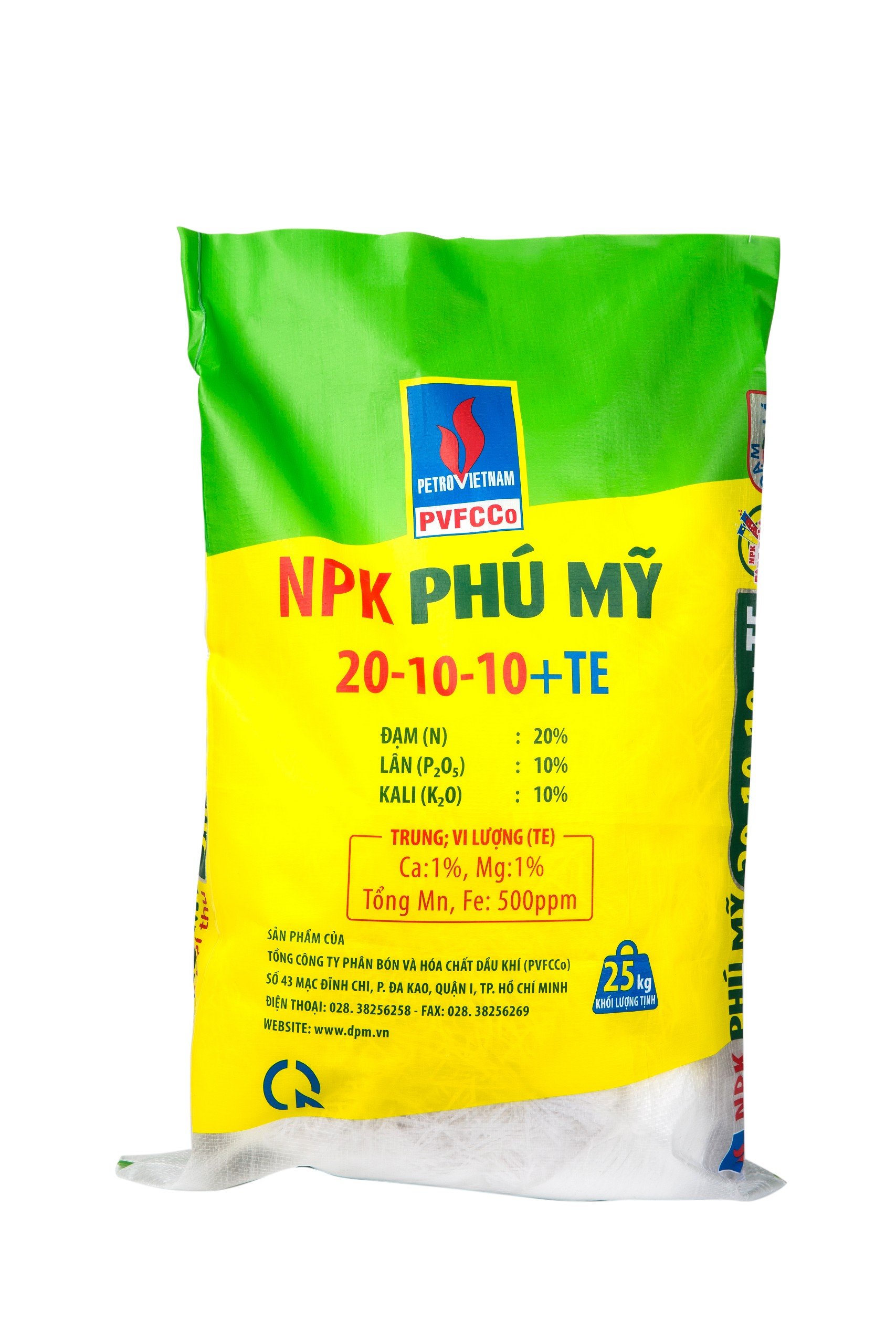

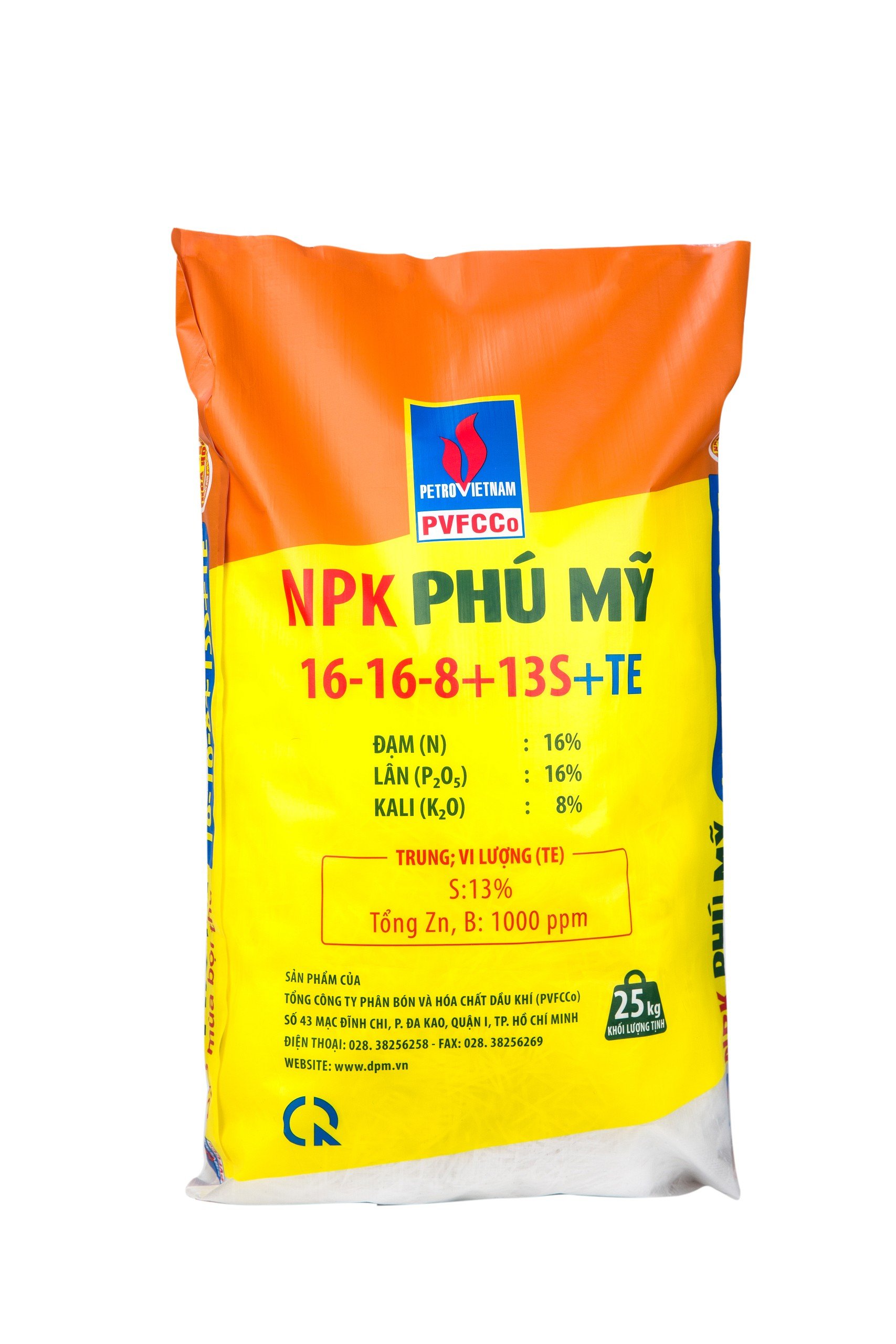

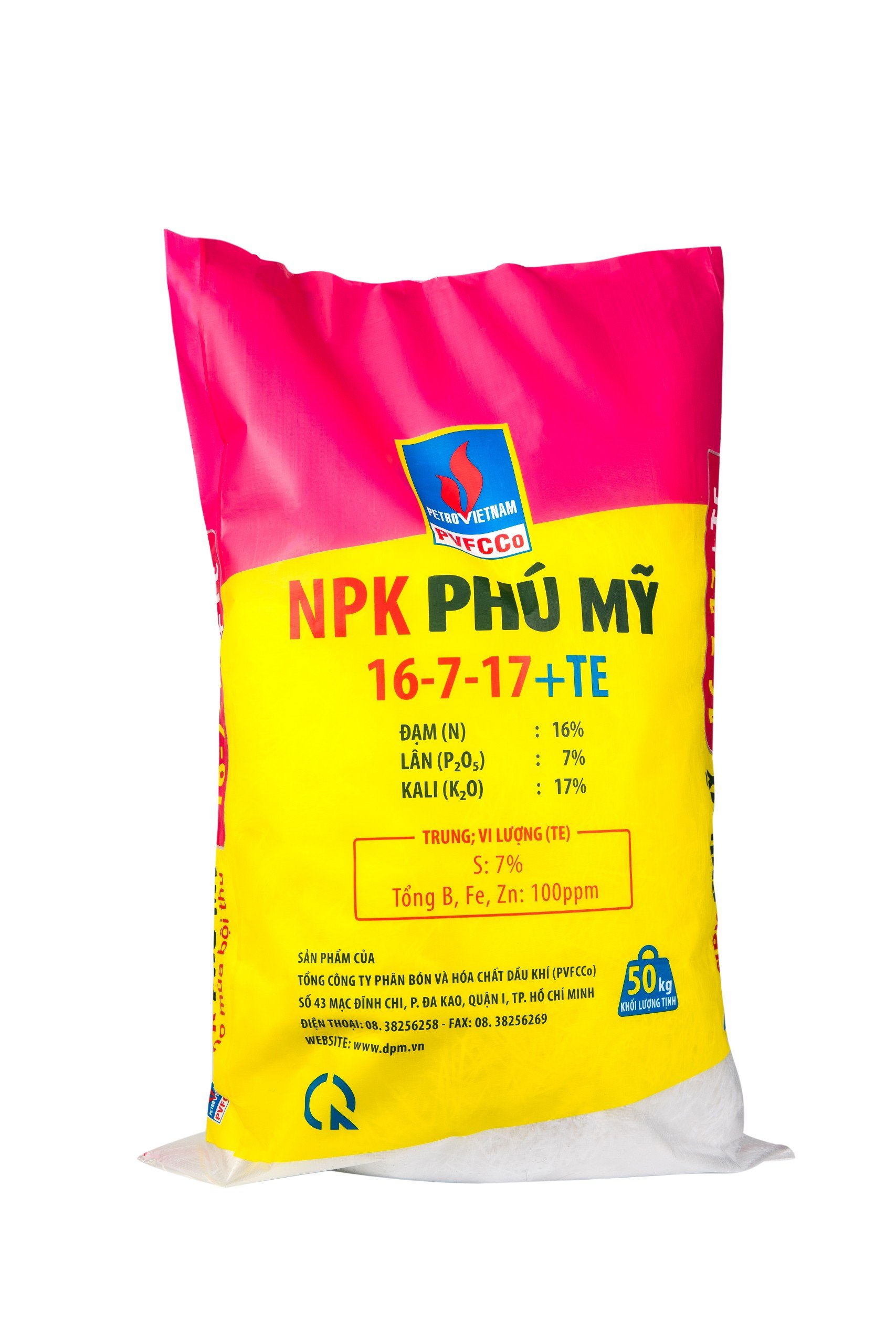

Product images